In the realm of automation in the industrial sector, the incorporation of robotic arms has become a transformative force, reshaping the world of production and manufacturing processes. The advent of modern technology has made robotic arm – often known as Arm robot industrial – indispensable. They offer unmatched precision, efficiency and safety in a wide range of industries. This article examines the capabilities of robot arms. They also discuss their impact on the modern business environment and the advancement in industrial automation.

Robotic arms or robot arms are versatile mechanical devices that mimic the functionality and endurance of human hands. They are extensively used in many industries, including automotive manufacturing as well as electronics assembly and pharmaceuticals. They can perform repetitive, intricate tasks with unparalleled precision. Robotic arms are programmable, allowing for seamless integration in diverse production settings. They offer a dynamic range of capabilities and can adapt to the changing demands of operations.

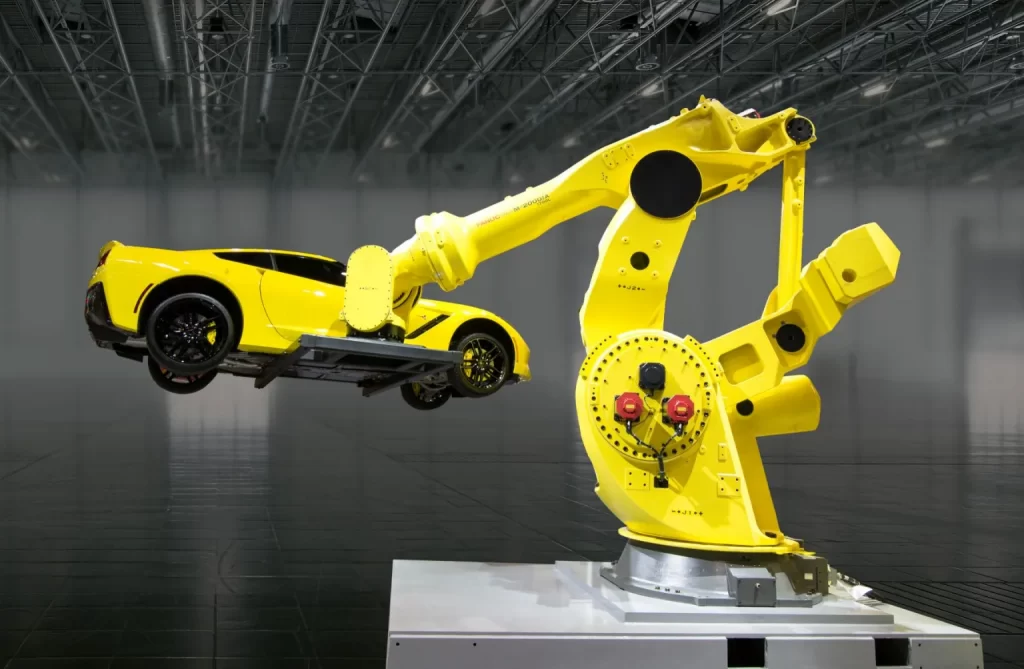

The robotic arm the foundation of modern automation, represents an advanced kinematic chain made up of movable joints that are capable of turning and executing linear displacements with incredible agility. This enables the robotic arm to maneuver through complicated spatial arrangements and move objects with meticulous care, all while ensuring optimal safety for human operators. Robotic arms are now essential to businesses, allowing them to streamline production processes and increase the efficiency of operations.

End effectors are a key feature of robotic arms. They function as an equivalent function for human hands. End effectors, which are typically designed to perform particular tasks, play an essential role in determining the scope of robotic arms’ applications. Robot hands equipped with specialized end effectors can perform everything from grasping and lifting heavy loads to delicately assembling complex parts.

In the contexts of industrial automation and robotic arms, a whole new age has been opened into innovation and productivity. Businesses can optimize their manufacturing processes through making use of the capabilities of robotic arms. They also reduce human error and increase the quality of products. The seamless integration between robotic arms and automated systems has resulted in significant efficiency improvements, allowing companies to meet the demands of their customers with unmatched speed and precision.

The impact of robotic arms goes beyond simple automation. It encompasses the fundamental redefinition of industrial processes. Industrial robotic arms do more than improve existing manufacturing workflows, but they also pave the way for innovative production techniques. Robotic arms are able to operate in hazardous and challenging conditions. This has improved workplace safety, while also unlocking new opportunities for complex manufacturing operations.

In addition, the evolution in robotic arm technology led to the development of innovative end-effectors that satisfy specific needs of industry. These sophisticated end effects, equipped with the most advanced technology for gripping and sensory, have broadened the range of uses for robotic arms. They enable businesses to tackle a variety of manufacturing issues with a speed that is unmatched.

As Australia is embracing the potential of robotic arm automation companies are offered a transformative opportunity to elevate their operational capabilities and compete. Integrating robot arms into industrial workflows is a great way to boost productivity, revolutionize manufacturing and propel growth. With a concentration on high-precision engineering and effectiveness, robotic arms will allow companies to reach the highest levels of efficiency in their processes.

In the end, the integration of robotic or industrial arms is an important step in the development of industrial automation. With their unparalleled accuracy, flexibility, and safety features robotic arms have revolutionized the capabilities of modern manufacturing, offering companies a competitive advantage in an increasingly competitive market. Australia is taking advantage of the transformative potential of robotic arms technology. Businesses can reap the rewards of improved productivity, operational efficiency, and innovation.