CNC machining has become a powerful force in the field of modern engineering. It is changing the way we create and manufacture intricate parts. CNC machines are able to attain unrivalled precision. From CNC Machines to CNC Mills, the world of industrial automation has been reshaped and Australia stands at the leading edge of this technological advancement.

CNC machining works by using the principle of subtractive manufacturing. This means that it removes material rather than adds to it in order for raw materials to be transformed into precision-crafted components. CNC Machines, the marvel of technology at the center of this technological advancement, are the foundations of manufacturing precision.

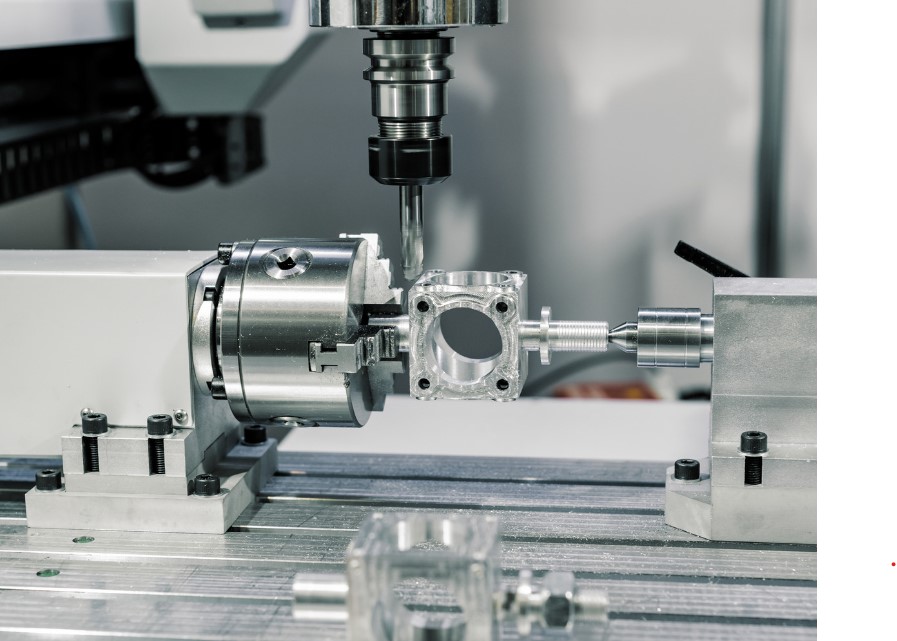

CNC machines, often known as digitalized computers, automate and oversee the movements of industrial machines. The digital code is used to guide the cutting machines’ high-speed cutters, which transforms a solid block of material into the desired shape. The integration of CNC Machines and computers is especially apparent in large industrial facilities.

The mechanics of CNC machine machining are complex and fascinating. CNC Mills begin with a solid piece of material, and then use cutting tools that are high-speed to create the desired shape. CNC machining has an unmatched accuracy, making it the most preferred method for industries where accuracy is paramount.

The CNC Machine industry in Australia is thriving due to cutting-edge technology and a robust sector of the industrial market that is driving the development of. CNC Machine Australia is an Innovation hub in which industries like aerospace, electronics and automotive rely on CNC machining to achieve unmatched accuracy and precision.

CNC Mills have a major impact on the future of manufacturing. These machines, which are controlled by computer code and produce precise parts for various industries, show versatility. The precision and efficiency of CNC Mills make them indispensable tools in the hands of highly skilled engineers and designers.

CNC machining provides many advantages, which go far beyond the traditional manufacturing methods. One of the biggest advantages is the capability to create complex and intricate components with high accuracy. CNC Machines’ digital nature allows for rapid prototyping and cuts down on time and costs.

CNC Machine Tools, another essential element of the technological ecosystem, contribute significantly to the efficiency of CNC machine. These tools include a wide variety of tools that can be used to assist in the machining process. They can be used to cut, shape and drilling, or for finishing. The synergy of CNC Machines and CNC Machine Tools provides a seamless workflow while maximising precision and minimising waste.

Industries across the spectrum have adopted CNC machining for its revolutionary capabilities. CNC machine is an essential tool in aerospace to create intricate components which require the highest level of precision and accuracy. CNC machining can be used to create complex components for infrastructure and machines in the energy industry.

CNC machining is utilized in a variety of industries, including the electronic and automotive industries. CNC machines are able to meet the requirements of both electronic and automotive industries. CNC machineries are used in a wide range of applications, from creating engine components to creating complex electronic circuits.

In the end, CNC machining has redefined the modern landscape of manufacturing, with CNC Machines, CNC Mills and CNC Machine Tools being the foundations of the technological revolution. In Australia and around the world, the precision, efficiency, and versatility of CNC machine tools continue to shape the future of engineering, paving the way for innovation and excellence in every industry it touches.