Computer Numerical Control, or CNC has revolutionized manufacturing and engineering fields in recent years. By integrating digital technology with traditional manufacturing processes, CNC machining has emerged as a dominant method for producing high-precision parts and components in a variety of industries. This article delves into the mechanics, benefits, and diverse applications of CNC machine machining, and highlights its impact on the modern engineering.

The mechanics of CNC Machining

CNC Machining, also referred to as subtractive manufacturing, is a process that removes material to form a desired form from a piece metal. The process is controlled by computer software pre-programmed to dictates the movements of the machine. The code that is generated for CNC machines varies based on the specific kind of machine as well as the level of complexity of the component being produced. However, the fundamental concept remains the same: a high-speed cutting machine precisely cuts away materials to create the finished product.

The accuracy of CNC machining is one of its most significant advantages. The digitalized nature of the process allows for incredibly accurate and reliable production, minimizing human error and making sure that batches are uniform across. This level is critical in industries like aerospace, medical devices as well as automotive manufacturing where minor deviations could result in grave consequences.

Digital Computers and their role in CNC Machine Operations

The integration of digital technology is at the core of CNC machining’s efficiency and accuracy. CNC machines are controlled by special software that automates the whole manufacturing process. The software converts CAD models into precise instructions that the CNC machine follows in order to produce the part. These instructions include everything from the speed and direction of the cutting instrument to the depth and angles of each cut.

In industrial facilities with large scales, the computers are often directly integrated into the CNC machines. This integration permits continuous control and communications. This integration allows for real-time monitoring, which guarantees optimal performance and reduces the amount of downtime. The automation of CNC machineries also permits continuous operation, greatly increasing productivity and cutting down time to market.

CNC Machining: Its Advantages

CNC machining is a superior method for manufacturing. The ability to create complex, intricate components with high-precision is one of the most significant advantages. CNC machining’s accuracy eliminates the need to make manual adjustments and rework. This reduces waste and improves efficiency. CNC machines can also be used in a continuous manner and are perfect for production runs that are large.

CNC Machining also has another advantage that is its versatility. It is possible to utilize the same CNC machine for a variety parts by simply changing its program. CNC machining has a high degree of adaptability, which makes it perfect to use for prototyping. It is also used for mass production.

Automating CNC machineries improves the safety of workers. By reducing the requirement to use manual interventions, the risk of accidents and injuries is reduced. CNC-machined products are more reliable, perform better and contribute to the brand’s reputation and satisfaction.

Industries Benefiting from CNC Machining Services

Efficiency, precision and flexibility are the primary advantages of CNC machining. CNC machines are essential in the aerospace industries, where they produce critical components that must be in compliance with safety and performance specifications. CNC machines are utilized in the medical device industry to create sophisticated implants and surgical instruments, where accuracy is key.

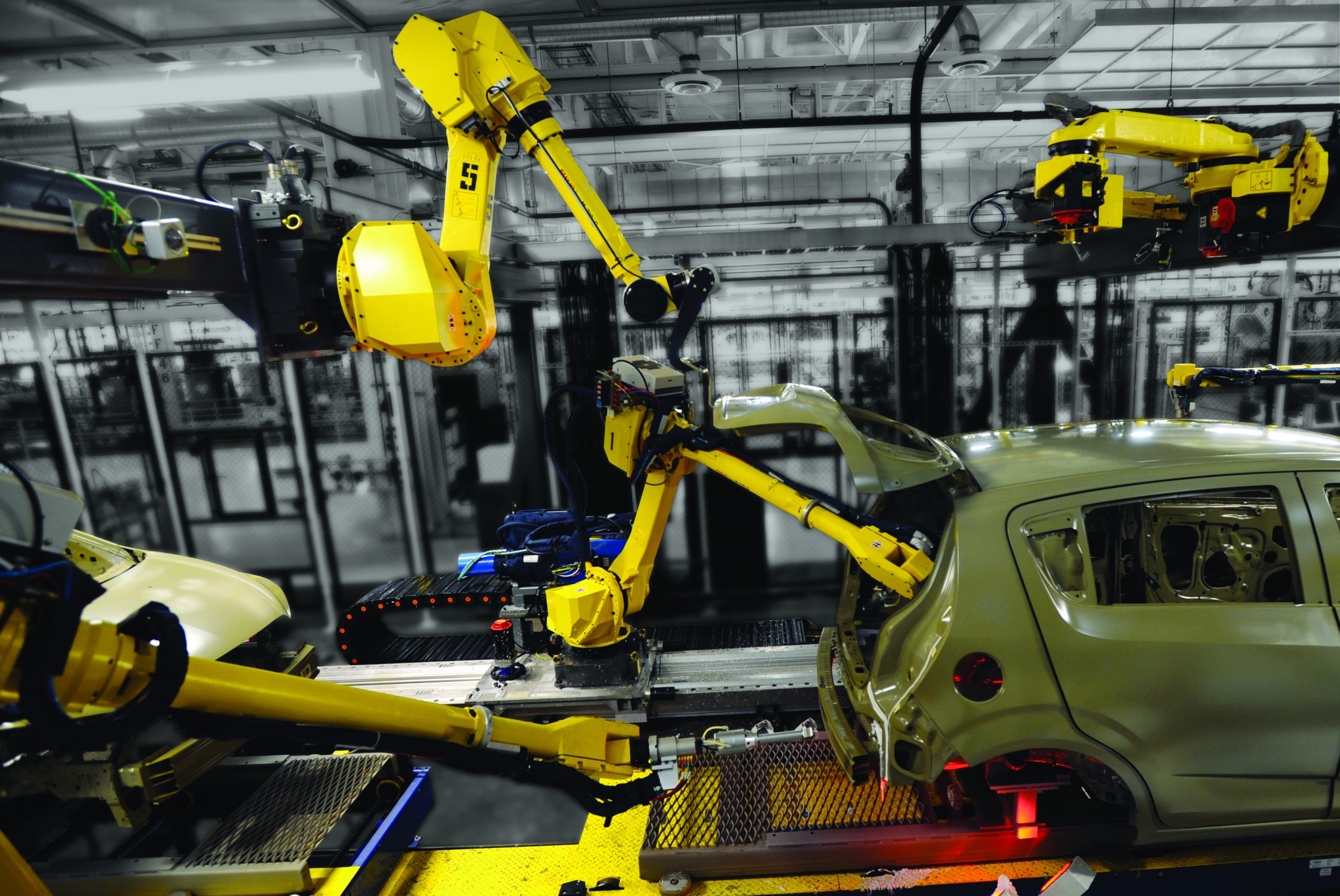

CNC machineries are widely utilized in the automotive industry to make engine components and transmission parts. It’s also used for intricate interior and external features. Electronics also benefit from CNC machineries, which are able to create small, intricate components for consumer electronics and communications devices. The art and jewelry industries also make use of CNC technology to create custom pieces as well as intricate designs.

The Future of CNC Machining

CNC machineries will continue to advance as technology advances. The capabilities of the CNC technology will further be enhanced by technological advancements like multi-axis machines as well as additive manufacturing and the development of advanced materials. Machine learning and artificial intelligence will also likely enhance the efficiency and precision of CNC machine machining.

CNC machineries, with their unmatched precision, efficiency and flexibility, has had an enormous impact on the field of engineering. The ability to create intricate parts with high precision makes it an invaluable tool in a variety of industries. CNC manufacturing, as the technology evolves will remain a key component in manufacturing’s future.